The Scientific research Behind the Longevity of Ceramic Coating Philadelphia Applications

The Scientific research Behind the Longevity of Ceramic Coating Philadelphia Applications

Blog Article

Why Ceramic Layer Is the Ultimate Option for a Flawless End Up

Ceramic layer has actually emerged as a leading option for those looking for a remarkable finish for their cars, thanks to its remarkable longevity and safety features. What factors really set ceramic finish apart?

What Is Ceramic Layer?

When applied correctly, ceramic finish produces a hydrophobic surface that drives away water and dust, making it easier to preserve and cleanse. Unlike traditional waxes or sealers, which generally provide temporary security, ceramic coatings can last for numerous years, depending upon the product high quality and application approach. The procedure of using ceramic coating requires careful prep work, consisting of thorough cleansing and in some cases paint improvement, to make sure ideal bonding and efficiency.

Ceramic finishings are not restricted to automotive surfaces; they can also be utilized on numerous materials, including glass, metal, and plastics, supplying a versatile solution for improving protection. On the whole, ceramic finishing represents a substantial improvement in surface area defense modern technology, integrating both useful and visual benefits for a variety of applications.

Advantages of Ceramic Finish

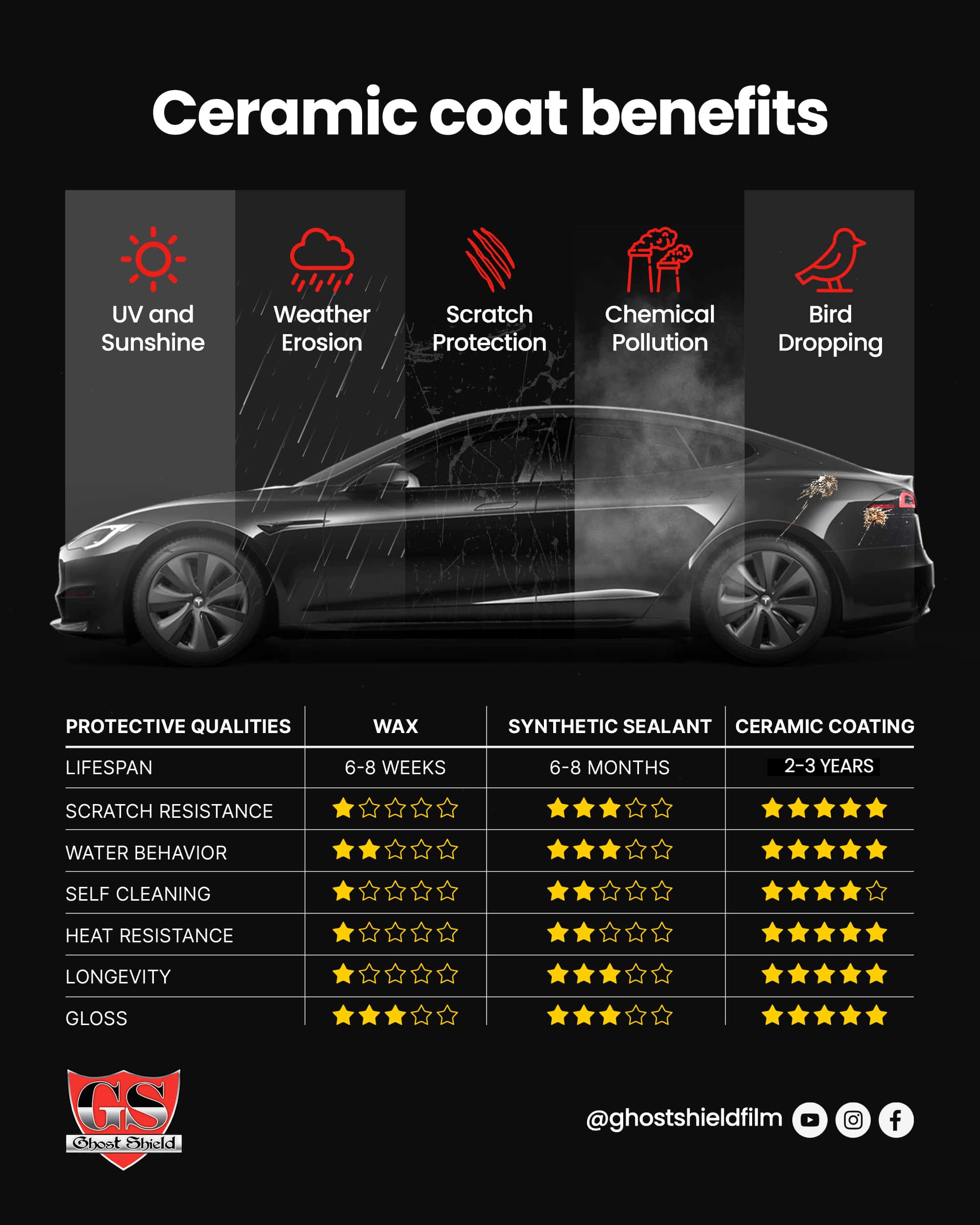

While several surface area defense alternatives exist, the advantages of ceramic layer attract attention as a result of its unique residential properties and long-lasting efficiency. Among the main benefits is its phenomenal resilience. Ceramic Coating Philadelphia. Unlike traditional wax or sealers that require frequent reapplication, ceramic coatings supply a resistant layer that can last for a number of years, significantly minimizing upkeep efforts

An additional notable advantage is enhanced defense against ecological contaminants. Ceramic finishes produce a hydrophobic surface that repels water, dust, and numerous toxins, making it simpler to cleanse. This function not only maintains the lorry's look however additionally decreases the danger of corrosion and oxidation, especially in extreme weather conditions.

Moreover, ceramic coatings use superior resistance to UV rays, preventing fading and degradation of paint in time. This UV defense is important for maintaining the aesthetic worth of surfaces and vehicles exposed to route sunlight.

Additionally, the glossy finish attained with ceramic layer enhances the overall visual charm, giving surface areas a showroom-quality luster. Overall, ceramic coatings represent a significant advancement in surface area protection technology, providing enduring advantages that cater to both useful and aesthetic requirements.

How It Works

Understanding the science behind ceramic finishings discloses exactly how they supply such amazing protection and durability. At its core, a ceramic layer is a liquid polymer that chemically bonds with the lorry's manufacturing facility paint. This bonding develops a safety layer that is both hydrophobic and oleophobic, repelling water, dust, and oil. The main element of a lot of ceramic layers is silicon dioxide (SiO2), which is obtained from quartz. This substance contributes to the coating's hardness and resistance to scrapes, UV rays, and environmental contaminants.

The application process involves numerous actions, including surface area prep work, which is critical to attaining optimum attachment. As soon as used, the coating undergoes a treating procedure, during which it solidifies and forms a semi-permanent bond with the paint surface. This bond is what identifies ceramic finishings from conventional waxes and sealers, supplying a longer-lasting protective barrier that can withstand for years.

Additionally, the thickness of the layer can improve its protective qualities, ensuring that it can stand up to extreme problems. Eventually, the scientific research of ceramic coverings integrates sophisticated materials with cutting-edge application techniques to supply an exceptional degree of protection and visual improvement for lorries.

Contrast With Standard Approaches

When compared to typical paint defense techniques such as waxes and sealers,The benefits of ceramic coatings end up being check my blog specifically apparent. While waxes use a temporary shine, usually lasting a few weeks to a number of months, ceramic layers provide a durable protective layer that can sustain for several years. This resilience dramatically lowers the frequency of reapplication, making ceramic finishes a much more cost-efficient solution over time.

Additionally, standard approaches frequently call for comprehensive prep work and several applications to achieve a sufficient degree of protection. On the other hand, ceramic coatings bond at a molecular level with the lorry's surface area, developing a durable guard against ecological pollutants like UV rays, acid rain, and roadway salts. This bond improves the vehicle's resistance to scrapes and swirl marks, which are widespread with conventional waxes and sealants.

Moreover, the hydrophobic buildings of ceramic finishes ward off water and dust, leading to much easier cleansing and maintenance. In contrast, wax and sealant-treated surface areas can attract gunk, requiring even more frequent cleaning - Ceramic Coating Philadelphia. In general, ceramic finishes not just provide remarkable protection however likewise deliver a more visually attractive and enduring coating, developing them as the recommended choice for discerning lorry proprietors

Application and Maintenance Tips

Making use of a foam applicator, use the layer in little sections, following the maker's standards concerning thickness and overlap. Allow sufficient treating time in between coats, see here now typically 24 hours, to make certain correct bonding. After application, it is crucial to stay clear of direct exposure to water or rough elements for a minimum of a week to allow the finishing to totally treat.

Additionally, making use of a ceramic maintenance spray can improve the finishing's hydrophobic residential properties and longevity. Normal evaluations for any kind of indicators of wear will aid keep the layer's honesty and protect that beautiful coating.

Verdict

In final thought, ceramic coating emerges as an exceptional alternative for accomplishing a perfect auto finish. By forming a durable bond with factory paint, ceramic layer efficiently shields against scratches, UV rays, and environmental contaminants.

Report this page